QUALITY CRAFTSMANSHIP

Single & Dual Shaft Lump Breakers

Cost-effective Solutions that save you money!

Equipment

For Specific Needs

What can Brown’s do for you?

Get Deatils

Round Separators & Dewatering Equipment

Grinders / Hammermills

Industrial Magnets

Rebuilt & Reconditioned Screeners

Single & Dual Shaft Lump Breakers

Brown’s Supply provides Schutte Hammermill Products, ruggedly built to outperform and outlast its competitors. Lump breakers are ideal for most common de-agglomeration applications, and where flowability is the goal. Industrial hammer mills and jaw crushers are the size reduction equipment of choice for processing large, blocky and/or abrasive materials.

Brown’s Supply offers an extensive line of Schutte Hammermill lump breakers, industrial hammer mills, and jaw crushers. All models are custom configured to suit the user’s material and production goals. Backed by Brown’s Supply and the Schutte Hammermill reputation with thousands of installations around the world, and nearly a century’s worth of experience, Schutte Hammermill has a solution for your size reduction challenge.

High Capacity Single & Dual

Rotor Lump Breakers

High Capacity Single Rotor Lump Breaker

High capacity, single rotor, hammer and comb design. Ideal for most de-agglomeration applications. Ranging in sizes from laboratory scale to heavy duty industrial, the BD Series Lump Breaker is available in carbon or stainless steel with a hammer and comb design tailored to individual applications. Various rotor speeds are available to optimize performance on a variety of materials reducing dry and/or or hardened agglomerates to a flowable end product.

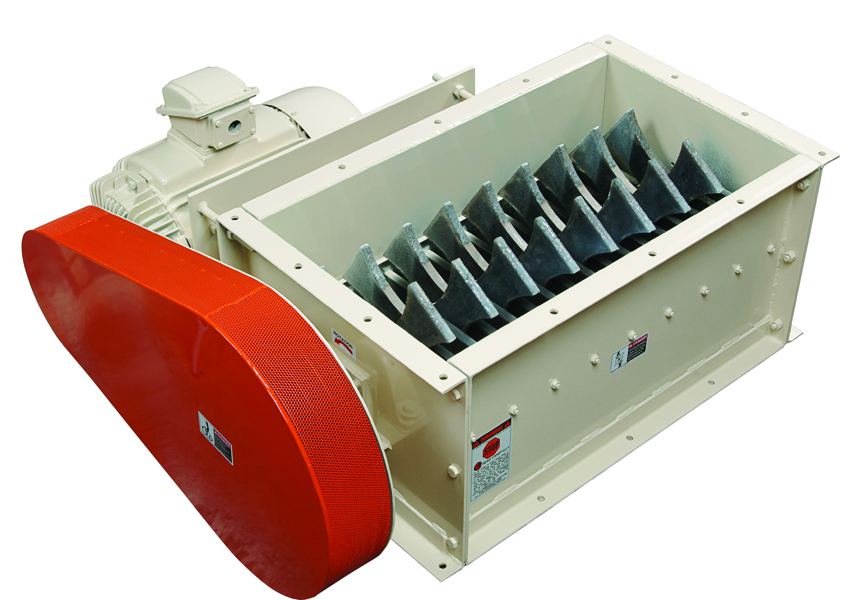

High Capacity Dual Rotor Lump Breaker

The KE Series is a high capacity lump breaker featuring a dual rotor design and is ideal for high tonnage and tough to process materials.

Ranging in sizes from laboratory scale to heavy industrial, the KE Series is available in carbon or stainless steel construction with dual counter- revolving, high torque rotors tailored to individual applications. Various rotor speeds and cutter teeth tolerances are available to optimize performance on a variety of materials reducing dry and/or hardened agglomerates to a flowable end product .

Products

Hammermills

Replacement Screens

Boots/ Sleeves

Balls

Rebuilt & Reconditioned Screeners

Recondition your machine to exact OEM standards ensuring your machine will run efficiently for years to come.

Interested

Join Our Team

Distributor Opportunities

Size Reduction

Equipment & Machines

Industrial Magnets

Rebuilt & Reconditioned 80 & 50 Series Machines

Parts

Call

(402) 721-7899

info@brownssupply.com